R Pump

Internal gear pumps

Description

For liquids of any viscosity and temperature, which can be corrosive, abrasive and dangerous for the environment. Non pulsating constant flow, therefore no vibrations on fittings, valves or couplings. Full performances are available in either direction of rotation. It can also be requested with heating jackets, with ports at 90° or 180°.

Heavy-duty construction optimized for rare maintenance. Produced in different versions depending on the specific application. Used by transfer, dosage, processing, load and unload.

In chemical, ink, paint, construction, chocolate and oil-industry, in refineries and storage facilities. Also with ATEX Certificate.

Working principle

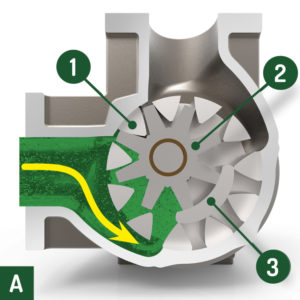

The R – internal gear pumps are self-priming positive displacement rotary pumps. Two gears generate the flow: the rotor (1) and the idler (2) . The rotor moves the internal idler.

As the gears rotate, liquid is drawn into the spaces created between the gears and smoothly moved toward the discharge port, were the divider (3) , called crescent, closes the free space between the two gears.

When the gears mesh, the liquid is slowly forced out of the pump. The result is a constant, smooth flow with no pulsations.

Video of the Working Principle

Advantages

- Self-priming.

- The capacity is directly proportional to the rotation speed.

- Non pulsating constant flow, therefore no vibrations in fittings, valves or coupling.

- No foaming or churning of the liquid.

- Only one shaft seal or with magnetic coupling.

- Heating jacket around the casing in one cast.

- Full performance is available in either direction of rotation.

- The casing can be rotated and delivered with 90° or 180° (in-line) ports.

- Relief valve against over-pressure incorporated in the pump.

- Heavy-duty construction optimized for rare maintenance

Typical Applications

- Additives

- Adhesive

- Asphalt

- Bitumen

- Chemicals

- Chocolate

- Coal Tar

- Coatings

- Colours

- Cream

- Creosote

- Diesel Fuel

- Emulsions

- Epoxy resins

- Fats

- Foams

- Fuel oil

- Gasoline

- Gelatine

- Glucose

- Glue

- Glycerine

- Glycol

- Grease

- Heat transfer oil

- Hot melt

- Ink

- Isocyanate

- Kerosene

- Lacquer

- Lube oil

- Mineral oil

- Molasses

- Naphtha

- Oil

- Paint

- Paraffin

- Petrol

- Pitch

- Polymer

- Polyol

- Printing ink

- Resin

- Soap

- Starch

- Tar

- Varnish

- Viscose

- Wax

…and many more.

Construction

Bare shaft

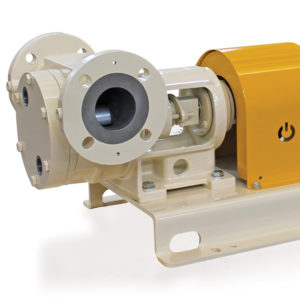

Bi-Block

Bi-Block on base plate

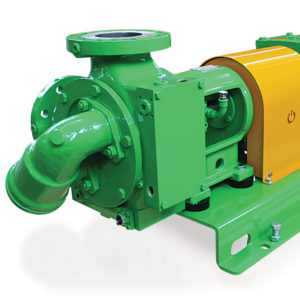

Classic

On Trailer with 4 wheels for flat ground

Options & Spare parts

Flanged ports DIN or ANSI with ¼” threaded holes for Vacuum-meter and Manometer.

Casing with the threaded ports (available for the R 35 & R 40 Pumps).

Idler: available in Gray Iron, Stainless Steel or Hardened Steel.

Rotor: available in Steel, Stainless Steel or Hardened Steel.

Pin: available in Hardened Steel, Stainless Steel or Tungsten carbide.

Bushings: available in Gray Iron, Sintered Iron, Carbon-graphite, Sintered Bronze, Bronze, Hardened Steel or Tungsten carbide.

Packing gland: available in GFO© Graphite filled PTFE or White Lubricated PTFE (Food grade).

Mechanical seal aviailable in different materials.

Quench reservoir (+O2) to keep a quench liquid inside the mechanical seal, preventing any contact between pumped liquid and air.

Mechanical seal with secondary packing gland in order to continue to work even with broken mechanical seal.

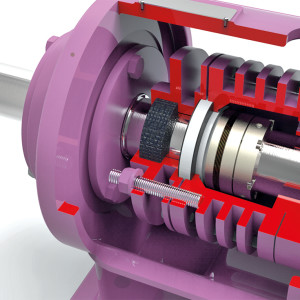

Cartridge mechanical seal aivailable in different materials.

Seal-less with heavy-duty magnetic coupling.

Safety-relief-valve against over-pressure integrated in the pump.

Bearing housing with external oversized and maintenance-free ball bearing to take axial and radial loads.

Base plate with grounding.

Victor-SX elastic coupling.

Victor-PX super-elastic coupling.

Flender-BDS flexible coupling for the Atex pumps.

Heating device on Victor R pumps

Heating jacket around the casing in one cast with flanged ports.

Heating jacket on the cover (+R2) for cast iron & stainless steel pumps.

Heating jacket on the cover (+R2) with flanged ports.

Heating jacket around the casing with counter-flanges to weld.

Heating plates on the casing with threaded ports (+R3).

Integrated heating jacket all around the pump.

Port Arrangement

90° Position 1

45° Position 2

90° Position 3

90° Position 4

45° Position 5

90° Position 6

180° Position 7

180° Position 8